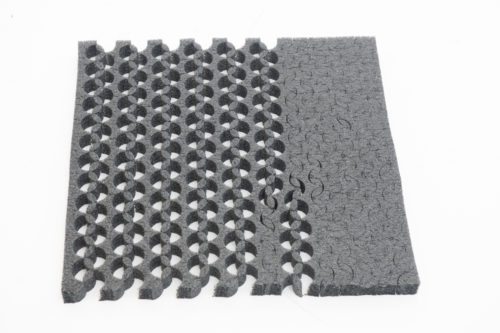

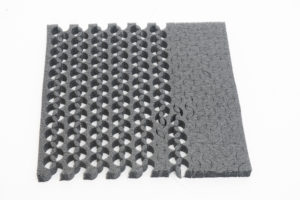

Designed to hold a large array of items from large and delicate instrumentation to smaller items like glassware and other fragile products, custom foam case inserts are an easy way to safely transport your goods. Any number of shapes or patterns can be crafted into the foam using one of our many contouring and cutting fabrication processes.

Specifications

- Foam Fabrication ProcessesDie-Cutting

Hot Wire Cutting

Molding

Routing

Water Jet - Custom Flexible Foam ExamplesDie Cut Gasket Foam

Routed Foam Case Insert

Saw Cut Delicate Piece Holding Insert - Contoured and Molded Foam TypesPolyethylene

Polystyrene

Polyurethane

Other closed cell foams

Other expanded foams

- Foam Insert Case ApplicationsBlow Molded Tool Boxes and Cases

Corrugated Boxes

Delicate Glass Components

High End Computer Hardware and Electronics Transport

Musical Instrument Cases

Shipping Crates

Soft Tote Bags

Wooden Crates - Foam Insert FeaturesAnti-Static

Available in Large Variety of Colors

Block and brace

High Recycled Content

Prevent shock and vibration

Temperature Insulation

Void fill

Water Repellent