Expanded Polystyrene, or EPS, foams are available for a number of applications from protective end caps for fragile equipment, to thermal insulation for medical perishables and foodstuffs, to architectural structure applications. The expanded polystyrene foam is often the most economical choice, and can be shaped and custom formed to fit boxes, crates, or tote bags, as well as made into the shipping container itself, such as a picnic cooler or a medical transport case. The versatility of EPS foam lends itself to many other applications and is an excellent choice for many projects.

Specifications

Polyethylene (EPE)

Polypropylene (EPP)

Polystyrene (EPS)

Electronics

Food Products

Medical Products

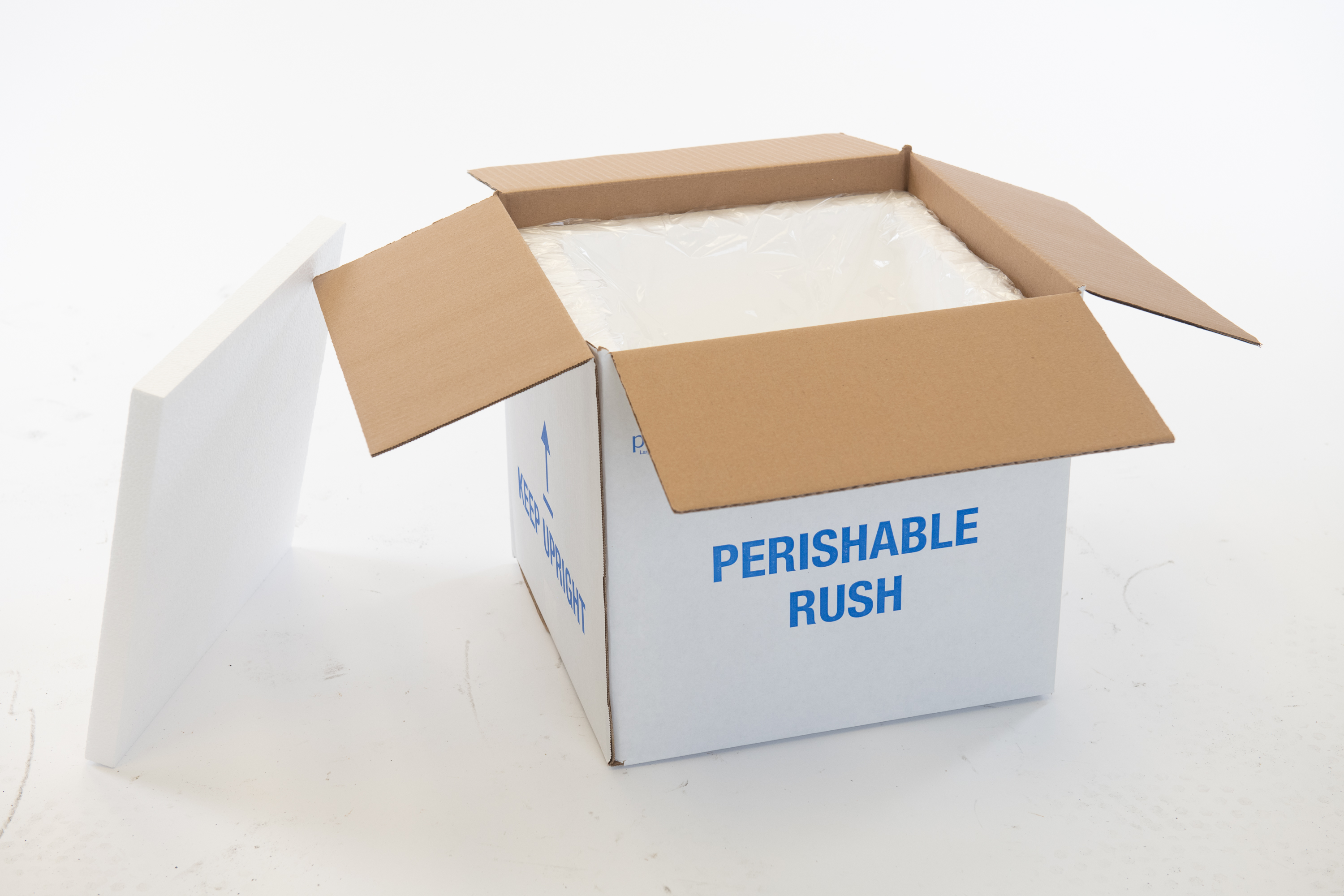

Perishables

Rigid coolers

Tote Liners

Gel Packs

RFID tags

Temperature sensors

Fungus and Bacteria Resistant Surface

Good Strength-to-Weight Ratio

High Thermal Resistance

Load absorption properties for heavier shipping contents

Low Thermal Conductivity

Moisture Resistant

Noise Reduction & Acoustic Sound Control

Same Low Toxicity Levels as Cardboard

Shipping Content Protection

Blood Collection Tubes and Sets

Critical Care Products

Diabetes and Allergy Syringes

Microbiology Testing equipment

Petri Dishes, Centrifuges, Filtration Units

Pulmonary and Cardiac Catheter Lab Kits

Sensitive Labware Equipment

Surgical blades, handles, and equipment

Chair Rails

Columns

Crown Molding

Custom Shapes for Architectural Industry

Expanding Impregnated Foam (EIF) Systems

Foam Concrete Pouring

Prefab Foam Construction

Theatrical Stage SettingsPackaging Standards and Compliance

Thermal Resistance, R, per inch (at 40° F)